If you thought knitting was just for cozy sweaters and warm blankets, think again. Researchers have developed a groundbreaking prototype machine that can knit in three dimensions, revolutionizing the way we think about furniture design. This innovative technique, aptly named “solid knitting,” aims to one day produce machines capable of knitting entire pieces of furniture.

The Science Behind Solid Knitting

How Solid Knitting Works

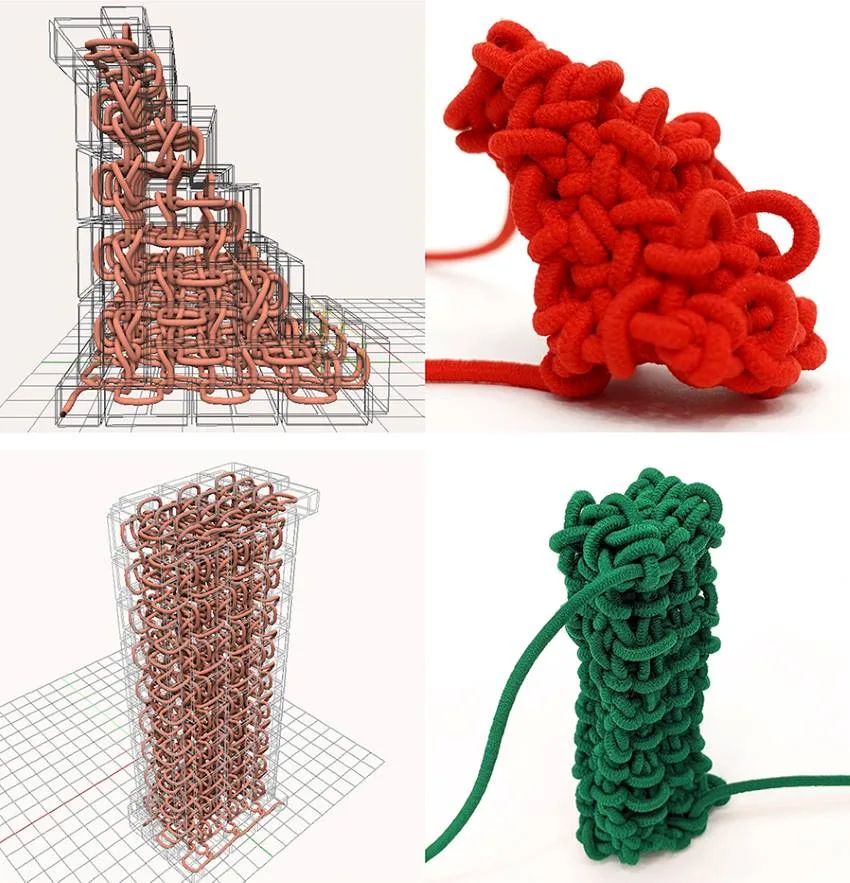

Solid knitting operates by layering knitted material much like 3D printing. However, instead of using melted plastic to bond layers together, each knit layer is intricately stitched to the previous one. This method results in a unique combination of strength and flexibility that traditional knitting or 3D printing alone cannot achieve.

The Prototype and Its Capabilities

Developed by a team at the Robotics Institute at Carnegie Mellon University in the US, this prototype was showcased at SIGGRAPH 2024, the annual Conference on Computer Graphics and Interactive Techniques in Denver, Colorado. The machine can create dense, firm, triangular, or rectangular prisms of varying lengths using elastic cord as yarn, which needs significant stretching to form the loops.

Advantages of Solid Knitting

Recyclability and Efficiency

One of the standout features of solid knitting is its recyclability. Unlike other 3D printing methods that require objects to be melted down and re-extruded into filament for recycling, solid-knitted items can easily be unraveled and re-knit. This makes the process more sustainable and efficient.

Versatility in Design

Solid knitting isn’t limited to machine production. The technique can also be applied to hand-knitting, allowing for the creation of larger, more intricate shapes such as sandals. Tutorials and software for creating machine-knittable 3D patterns are freely available online, broadening the accessibility of this innovative method.

Comparing Traditional Knitting and 3D Printing

Traditional Knitting

Traditional knitting is known for producing soft, flexible items like hats and socks. These items conform to the shape of the body but lack the structural integrity to maintain their form independently. Once you remove your socks, they become floppy tubes rather than retaining the shape of your feet.

3D Printing

On the other hand, 3D printing creates rigid objects that retain their shape but lack flexibility and softness. While these objects are excellent for structural integrity, they are not ideal for items that require comfort, such as shoes or sofas.

The Unique Benefits of Solid Knitting

A Middle Ground

Solid knitting bridges the gap between these two techniques. The objects produced through solid knitting have an internal structure that allows them to hold their shape, yet they remain much softer and more flexible than traditional 3D prints. This middle ground offers the best of both worlds, combining the comfort of knitted materials with the durability of 3D printed objects.

Potential Applications

The possibilities for solid knitting are vast. From furniture to fashion, this technique can be used to create items that are both aesthetically pleasing and functional. Imagine a sofa that contours to your body while providing robust support or shoes that are both durable and comfortable.

The Future of Solid Knitting

Exploring New Possibilities

The research team at Carnegie Mellon University has only begun to explore the potential of solid knitting. Co-author Mark Gillespie expressed excitement about the future applications of this technique, highlighting the diverse material properties and object types that can be achieved.

Innovative Designs on the Horizon

As solid knitting technology advances, we can expect to see more innovative designs and applications. The ability to create complex, customized shapes with varying levels of firmness and flexibility will open new doors in both the furniture and fashion industries.

Conclusion: A New Era in Fabrication

Solid knitting represents a significant leap forward in fabrication technology. By combining the strengths of traditional knitting and 3D printing, this technique offers a unique blend of comfort, durability, and sustainability. As the technology continues to evolve, the possibilities for solid knitting are limitless. From personalized furniture to custom-fit clothing, the future looks bright for this innovative approach to design and manufacturing.

FAQs

1. What is solid knitting?

Solid knitting is a fabrication technique that combines the principles of traditional knitting and 3D printing to create objects with both strength and flexibility.

2. How does solid knitting differ from traditional knitting and 3D printing?

Traditional knitting produces soft, flexible items that lack structural integrity, while 3D printing creates rigid objects that hold their shape but lack softness. Solid knitting offers a middle ground, producing items that are both durable and flexible.

3. What materials are used in solid knitting?

Solid knitting primarily uses elastic cord as yarn, which needs to be significantly stretched to form loops. This material choice allows for the creation of dense, firm objects.

4. Can solid knitting be applied to hand-knitting?

Yes, the technique can be applied to hand-knitting to produce larger, more intricate shapes. Tutorials and software for creating machine-knittable 3D patterns are available online.

5. What are the potential applications of solid knitting?

Solid knitting can be used in various fields, including furniture design and fashion. It allows for the creation of items that combine the comfort of knitted materials with the durability of 3D printed objects.